Your business runs on shipments. LOTS of shipments. Whether you’re receiving materials critical to your manufacturing process, sending out components to fuel your customers’ supply chains, or sending finished goods to be used and loved by consumers, shipments are a daily hassle.

But they don’t have to be.

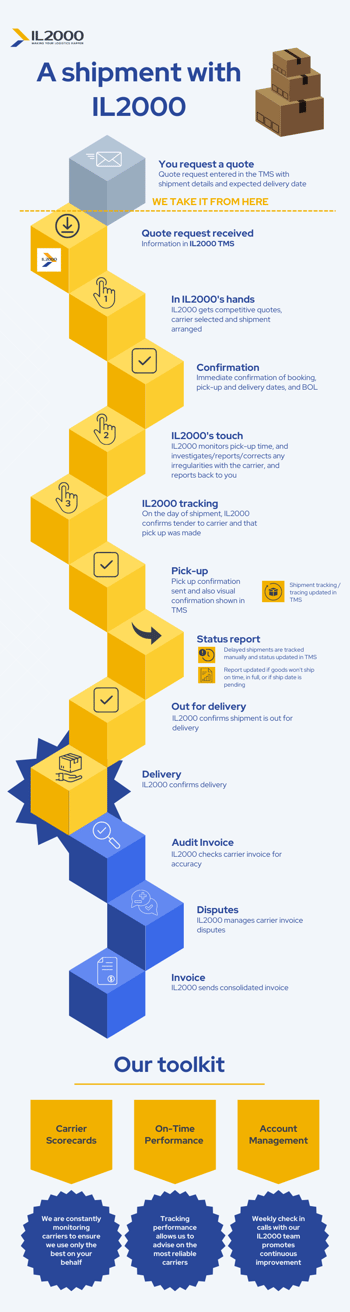

Walk with me, if you would, on a stroll through the workings of IL2000 and watch what happens to your shipment, start to finish, from initial tendering in our transportation management system (TMS) through final delivery. A bit like relationship coaches, we’ll work with you and your shipment until your process is streamlined, stress-free and reliable.

First, the request for a quote

First, the request for a quote

Did you know you can get an immediate quote with the IL2000 TMS? (Really, truly, here’s the video to prove it.) 98% of booked shipments move without issue, automatically. But what happens when they don't?

Let’s assume, in this instance, there's an issue. Here’s what happens next.

8:03 Quote request entered in TMS.

8:04 Turns out not all the booking details are there. Dimensions are missing. Sally in our team steps in and emails you requesting the missing data.

8:10 You go to the dock, find the dock manager, and get those dimensions. Then you email IL2000 back.

8:11 Sally reviews the complete data, puts the information in the instant booking system, finds the best carrier for that lane and delivery time, agrees to a negotiated rate, and books it. She sends you an email with your Bill of Lading (BOL), carrier pick-up information, and delivery timeline.

8:12 You receive the BOL and confirmation of the shipment pick-up and delivery times.

8:13 You pour your second mug of coffee and smile.

10 minutes from start to finish. A fiasco that usually took you and your team up to an hour of messing around with calls to carriers to arrange, and you still didn’t know if you ended up with the best rate or most reliable carrier.

Now you have a smoother and more streamlined start to your shipment and your day.

However, if you want more control over arranging your shipment, you can always use the instant pick-up scheduling in the IL2000 TMS. Here is, you guessed it, a video on how to do that.

Next, tracking

You can track your shipment directly in the IL2000 TMS (follow this easy video). But let's assume you want to rely on us. Here's what it looks like behind the scenes and what you see on your side of the magic curtain.

Day of pick-up: Sally and her team (because let's be real, this is a down-to-the-second critical job and occasionally Sally needs the bathroom) check the shipment and planned pick-up time. They see it is scheduled for later that afternoon and make a task to check back after the scheduled time. Once that time has passed, they check to see that it has, in fact, been picked up.

If yes, they move on to the next pressing shipment.

If not, they are immediately on to the carrier to figure out why, what the new scheduled pick-up time is, and whether or not this will affect delivery time. The team then emails you immediately so you can inform your customers of any delays before they happen. They also leave a note in the system so you can find and reference it later.

Once pick-up occurs, you’ll be automatically updated with the order status.

While in transit: Sally and Co. continue to trace your shipment throughout its journey. This is when they use their expert, advanced knowledge to help avoid delays caused by events -- like weather or strikes -- that would otherwise leave you powerless, trying to scramble for a way around the transportation snafu and probably spiking your coffee to make it through the next hour, let alone to the end of the day when you know your customers will be calling with complaints about deliveries that never arrived.

When we see a shipment is off-track, we'll intervene to correct the trajectory and update you right away. Again, this positions you to keep your customers abreast of any delays before they occur.

Day of delivery: Sally and her team watch your booking like a hawk, ensuring everything is on track. Once your shipment is delivered, they will inform you.

If the delivery time passes and there is a failed delivery, they get on the case, investigate why, and take immediate corrective action. They keep you in the loop so you, and your customers, aren't left wondering what's going on.

Not even for a minute. (59 seconds? Perhaps. We admit we’re only human.)

Once the delivery is marked complete, Sally moves on to your next order while your shipment transits through to our auditing department for review.

Last but not least, auditing

Billing errors. Ugh.

Carriers often add extra charges to an already agreed order. What do you do? Maybe you’ve given up trying to fight these because you waste countless hours while never getting charges reversed. Or perhaps your shipping department keeps making the same mistake and you’re charged a reweigh fee, but you’re not sure where it’s all going wrong.

Forget it all. Every. Last. Invoice.

The carrier bills us. We check the invoice against the order, check all charges, and fight the fights that need to be fought. (To be fought? Foughtted? Never mind, you can see where I’m going with this…) You receive already-audited, approved invoices. No more piles of invoices waiting to be disputed littering your desk. (Or a long list of flagged emails with invoice attachments if you prefer to work like a millennial.)

Also, by sending you a consolidated invoice, you only need to make one payment to IL2000. That’s it. One. Versus managing payments to sometimes 50 different carriers.

But in reality, our work starts even before the auditing process, helping you set up shipments properly. This Billing Errors 101 blog covers the basics and enables you to avoid pitfalls. We also check your shipment requests and eliminate the potential for things to go awry. By managing your billing, you get rid of the busy work and end up paying less on freight.

The other stuff

Reviews, carrier compliance, and recommendations to improve your supply chain: All those things sitting on your to-do list, we’ll do for you.

Here’s why they’re important.

Reviews: Let’s take something as simple as OTP, That's On-Time Performance, and track how often a carrier delivers on time. But there's so much more to it. We will show you the raw %, but also break it down into an adjusted performance score that shows which of it is on the carrier, which is beyond their control (like bad weather), and which is on you – such as misinformation in the booking details. If you meant three pallets but instead specified two, the truck shows up and doesn't have space for your order. Don't worry; we've already sorted that one out for you and reflected it in the carrier’s adjusted OTP score.

Then we’ll take you through that and other shipments, so you understand what’s happening behind the numbers.

This is where our Power BI dashboards come in handy – they’ll help you interpret the data and make better decisions in the future.

Oh, and we have to mention that you can easily and quickly find all your supply chain documents in the TMS. The last video, I promise.

Carrier compliance: There’s a lot that goes into selecting a carrier and ensuring they’re right for your business. Often it comes down to rate, but it shouldn’t be that simple. If you pay less but your claims go up, have you really made the best selection? If we see this happen, we’ll move a carrier off your preferred list and suggest you use a different carrier for that lane, balancing rate with quality.

We also move tons of stuff around daily, so we can negotiate good carrier rates on your behalf, and even get those pesky accessorials reduced if that’s what’s standing between you and using a better carrier for your shipments.

Here’s a recent article that covers carrier compliance tips on more detail, including OTP; lost and damaged shipments; capacity, rates, and transit times; and invoicing accuracy.

Recommendations: This is where we sit down with you every quarter and review your shipments, your processes, where you’ve saved money, and where you can save more. We discuss how you’re using the TMS and offer tips on how to use it more efficiently. We also review how your team and our team are working together and find ways we can continue to take on more of your workload and streamline your process.

Be future-ready for all freight shipments with IL2000

Do you remember The Process (capital T, capital P) we used when we first ran a supply chain analysis on your business? Well, quarterly business reviews, where we discuss changes affecting your business and scope and build new solutions, are part of that. It's an ongoing process. Forever and ever.

Phew. Well, that’s what we do every minute of every day, every day of every week, and every week of the year. To take your shipment, and your business, from A to B.

That’s a day in the life of a shipment with IL2000.

If you're not currently experiencing such a seamless process, robust visibility, and continual savings while having time for that extra coffee, then send us a message. We can help.