"Describe what's in the box." That instruction sounds simple and benign. But even a minor omission in the description of the contents can be catastrophic. Make a mistake, fail to classify the material correctly and the result can be a loss of goods, transport vehicles and even life.

And you can’t rely on your intuition. We’ll explain why.

The obvious

Let’s start with what is probably a relatively familiar list of HazMat labels. These classifications include:

- Explosive, Gas (Flammable, Non-Flammable, Poison)

- Flammable Liquid

- Flammable Solid

- Spontaneously combustible

- Dangerous When Wet

- Oxidizer

- Organic Peroxide

- Poison Inhalation Hazard

- Poison

- Infectious Substance

- Radioactive

- Corrosive

- Class 9 (a catch-all label for all substances that don’t fit into one of the above classifications listed as Environmentally Hazardous Substances Liquid or Solid).

Are you having high school science lab flashbacks yet? If so, you'll remember that some substances are unstable and can explode or self-combust, especially when jarred or exposed to heat. Some are poisonous and should not be touched, inhaled or placed anywhere near foodstuffs. Others are corrosive and will eat through improper storage containers. Radioactive materials can leak dangerous electromagnetic waves or subatomic particles.

It stands to reason that goods with any of these classifications require careful and special handling. This includes packaging, loading and unloading, transportation conditions, hazardous endorsements for drivers, and even HazMat-certified carriers, shippers and drivers.

Some reputable carriers have an electronic system that cross-checks goods at the time of loading against cargo already in the truck and flags materials that cannot be loaded together. Others rely solely on the paper in front of them or the label affixed to the shipment.

While this may sound scary, HazMat materials are safely transported around the world every day. The problem comes when shippers mislabel these goods.

Let’s take an example. An electronics and small appliance wholesaler ships goods intended for retail outlets from Shanghai to Las Vegas via the Port of Long Beach. The items are boxed, stacked, shrink-wrapped on palettes and then loaded into a truck at the manufacturer's site.

Each pallet is labeled: Coffee makers, blenders, toasters, headsets, memory cards, and misc. The driver merely glances at the shipping documents, loads the shipments onto the truck, and then drives to a central transportation hub. The pallets are unloaded and reloaded into a shipping container alongside other cargo. Then, another vehicle transports the container to the port.

At the port, the container is loaded on board a behemoth cargo ship and strapped onto the stack. Right on top. Three days after setting sail with the sun beating down on the stack, the temperature inside the container starts to rise. The chemicals inside one lithium battery in a half-pallet of computers intended as store displays (you know, the Misc. shipment) begin to heat up. Due to a fault, the already thin separator thinned further and was breached, causing a short circuit. The battery hit 1000ºF and exploded. Next to it were three full palettes of highly flammable petroleum products.

Could a disaster have been averted with proper classification and labeling of the contents of that electronics container? Maybe, maybe not. But how containers are loaded, and which cargo is adjacent to or separated from other shipments is an exact science. Nothing should be left up to chance.

While this was an obvious example of "of course, you don't put lithium batteries in the sun next to explosive products," not all scenarios are this intuitive.

The not-so-obvious

Back to high school science class: Do you remember the experiments when materials would burn, explode or change forms (solid-liquid-gas) when exposed to various substances? Imagine those scenarios in uncontrolled situations, such as on a railcar, in the back of a truck, or at sea.

What if I told you that sand could sink a ship?

Granular cargoes such as crushed ore and mineral sands sink numerous ships every year. In fact, 10 ‘solid bulk cargo’ carriers have been lost at sea each year over the last decade.

Here’s what happens. Two-phase materials, such as sand, contain water between the solid particles. With minimal friction, the materials still act solid even though they contain liquid. But as the water pressure builds up, for example when loaded with a quayside conveyor belt or from the vibration and motion of the engine and sea during voyage, the cargo can liquefy.

That in and of itself may not be a problem, but when solid bulk cargo turns to liquid, it shifts and sloshes inside the ship's hold, making the vessel unstable. Now, imagine what happens if that liquid moves entirely to one side of the hold and then regains a solid state. The cargo is now critically off balance and the ship will list. If the load liquifies, shifts and resolidifies once again, the ship will tilt even further. Once the angle of list is great enough, water will enter the hull through hatch covers and the ship will no longer be able to recover from the rolling of the waves. The vessel will sink and take her crew with her.

The International Maritime Organization has a code governing how much moisture is allowed in solid bulk cargo but improper classification and rough loading work against the safety of ships and crews.

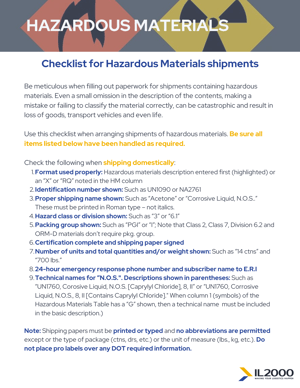

Checklist for Hazardous Materials shipments

Okay, we get that you are not standing dockside and determining how high and fast a conveyor belt drops sand into a hold, nor are you responsible for lithium battery faults. However, there are simple tips you can follow to move hazmat (and potentially hazardous) materials more safely.

Okay, we get that you are not standing dockside and determining how high and fast a conveyor belt drops sand into a hold, nor are you responsible for lithium battery faults. However, there are simple tips you can follow to move hazmat (and potentially hazardous) materials more safely.

Use this checklist and be meticulous when filling out paperwork for shipments containing hazardous materials.

Check the following when shipping domestically:

- Format used properly

- Identification number shown

- Proper shipping name shown

- Hazard class or division shown

- Packing group shown

- Certification complete and shipping paper signed

- Number of units and total quantities and/or weight shown

- 24-hour emergency response phone number and subscriber name to E.R.I. (Emergency Response Information)

- Technical names for "N.O.S." (Not Otherwise Specified). Descriptions shown in parentheses

Check the following when shipping containers and packages (non-bulk):

- Marked with proper shipping name and identification number

- Marked with technical name for "N.O.S." Descriptions show in parentheses in association with the proper shipping name

- Must be labeled unless “Limited Quantity” or “LTD QTY” is shown on the shipping paper after the packing group

- In good condition, properly sealed and valves closed

Placards: Vehicle shall not be moved until the driver affixes the required placard(s).

For a more detailed checklist, download the Checklist for Hazardous Materials shipments tips sheet.

You might also register with Chemtrec. This great resource offers an emergency call center and provides assistance for incidents involving hazardous materials of any kind.

A good 3PL is better than a hazmat suit

Partnering with a 3PL like IL2000 offers that added layer of protection for your domestic and international shipments.

At IL2000, we use only reputable carriers capable of handling hazmat properly and one of our hazardous materials experts will always double check your required documents. This gets your shipment safely on its way in no time.

Get in touch if you want to know your cargo is safe.