Consumer packaged goods (CPG) — you know, all those goods that consumers use up and replace frequently — food, beverages, clothes, personal hygiene, cosmetics, household products. Their packaging is usually easily recognizable and their brands prominent: Coca-Cola beverages, Ariel fabric care, Breyer ice cream, Prada shoes and Johnson & Johnson baby oil are a few that come to mind.

The CPG industry has never been more important than now, during the global pandemic, when keeping consumers supplied with the products they need for survival is paramount. But as consumers change how they live and work, so too do they change what and how they buy. Consumer packaged goods companies that adapt will emerge stronger and reap the benefits of long-lasting consumer loyalty. But with this comes the need for a more agile supply chain.

Brands, oh my!

Big brand companies dominate the market. In the fast-moving consumer goods (FMCG) segment, Switzerland's Nestle holds the title for the largest global company, followed by US-giants Procter & Gamble and PepsiCo. In fact, the world’s 40 largest FMCG companies generate over $1 trillion sales a year, reports Consultancy.uk.

That’s lots of brand products launched every year. But sometimes they make more of a thud than a splash in the market. So, just for fun, let’s look at some of the worst product failures from recent decades.

- The Evian Water Bra (2005). Oh yes, you heard right. A bra that could be filled with water supposedly to offer a cooler alternative to a "traditional" bra (read a bra that actually works) in hot months. It also had a pouch for storing a bottle of water in case any woman wanted to add to the weight already hanging off her rib cage. I can only imagine a man designed this contraption.

- Pond’s Toothpaste (2000s). This was a case of brand image being too strong. Consumers’ association of Ponds, created by Unilever, with beauty and skincare didn't allow for broadening the product range into teeth cleaning.

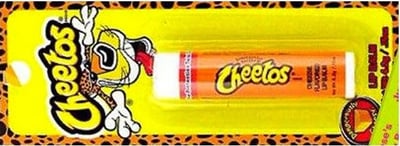

- Cheetos Lip Balm (2005). As if eating Cheetos doesn't leave enough residue on your lips…

- Colgate Kitchen Entrees (1982). Nope, not toothpaste-flavored frozen dinners, but the brand association was enough to restrict sales of beef lasagna and other savory meals.

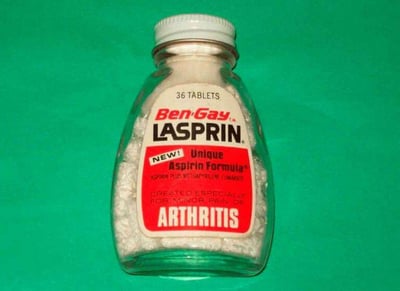

- Ben-Gay Aspirin (1990s). For when your headache needs a soothing icy-hot balm?

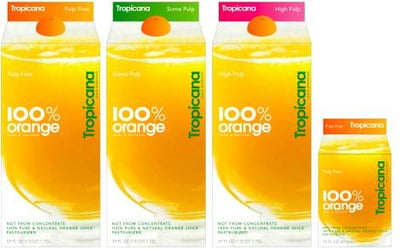

- Tropicana Orange Juice (2009). This was a case of a packaging redesign failure that caused a 20% decline in sales. Consumers couldn’t distinguish the product as easily on the shelf and felt the redesign made the juice look generic. After just six weeks, PepsiCo returned to the old packaging, but this fiasco cost the company around $50 million all in by some accounts.

- Bic Underwear (1998). The move from disposable products including pens, razors and lighters did not transition well into disposable panties and tights. Who would have guessed?

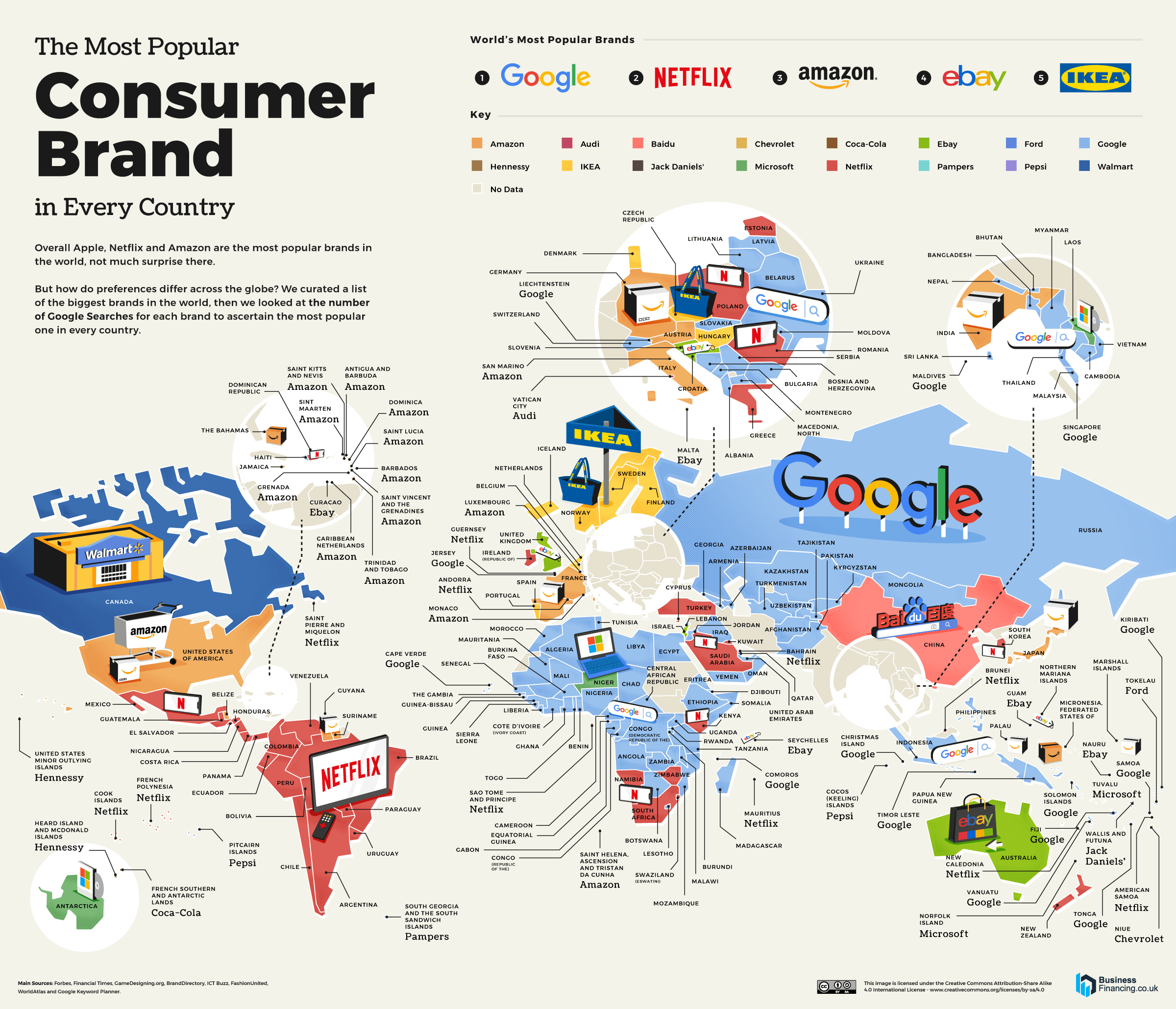

Giggles aside, reviewing product failures helps avoid faux pas in the future. But so does taking a look at the brands and products that get it right. This chart, created by Business Financing.co.uk, shows every country's most popular consumer brands. Go on — blow it up and check it out. You'll see that Walmart, Amazon and Netflix dominate the Americas, while Google has conquered most of Africa, Asia and Europe. But there are certainly CPG brands in there, including beverages like Coca-Cola, Hennessy, Jack Daniels’ and Pepsi, as well as baby care including Pampers.

Homebodies and Homebuying

Before we wander too far into the land of branding, let’s return to the discussion around catering to today’s consumers. As you can see from product failures in the past, consumers are opinionated, tied to their favorite brands and unforgiving. Usually. But the pandemic situation and the recent changes in lifestyle are opening new windows of opportunity.

According to PWC, CPG sales increased during the shutdown, with 50% of consumers trying new brands primarily via online purchases ( which were up 35%) with both store pick-up and home delivery. In fact, consumers were 1.8 times more likely to increase spending online if the household had children living at home. But the take-home message was 66% of consumers were likely to stick with the new brands. That's huge.

As the pandemic shifts into year three at the start of 2022, demand levels, price points and consumer behavior continue to be key sources of uncertainty. But many of the investments done now will continue to help manufacturers win in the future – from new capabilities, different cost structures, streamlined portfolios and a workforce with a different way of working.

The expectation shift

The CPG industry has shifted focus in order to keep up with consumer trends. According to SendPulse, these efforts span from marketing approaches that use tailored omnichannel marketing strategies to acquire new consumers, to different types of products, including a switch to private labels, self-care products and meal kits, as well as a careful balance of commodity and high-value specialty items. Customized products have also become very popular, as has the spotlight on sustainable goods.

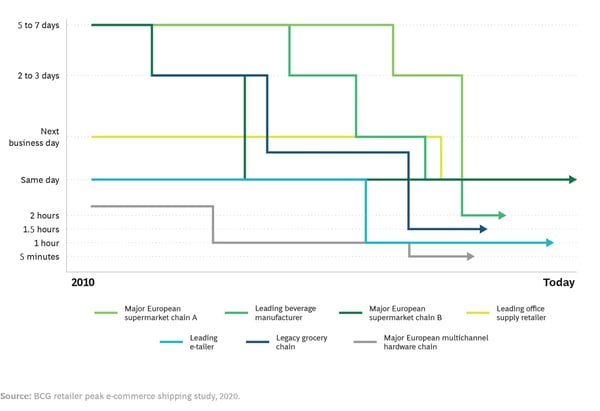

BCG hones in on shrinking lead times which used to be a forgiving 4 to 7 days for an order placed by a retailer and is now down to a day or two with extremely narrow drop-off times. This change is driven by consumers who want goods faster and are less tolerant of stockouts, especially online. The graph below shows delivery times shrinking over the past decade. Now, consumers expect their goods in mere minutes to hours rather than days.

Shrinking Delivery Times over the Past Decade reflect consumers' Ever-Growing Expectations

This expectation shift is driving CPG companies to look for alternative transportation routes, warehousing facilities and in some cases even raw materials suppliers. It’s important to note that for CPG companies that fail to provide stocks, the problem is more than empty shelves in retail outlets. With today's online shopping, smart algorithms hide unavailable products from search and page views, so not only is the product unavailable, but it is pushed out of sight and out of mind as other products become substitutions. A consistently underdelivered item may permanently lose market share.

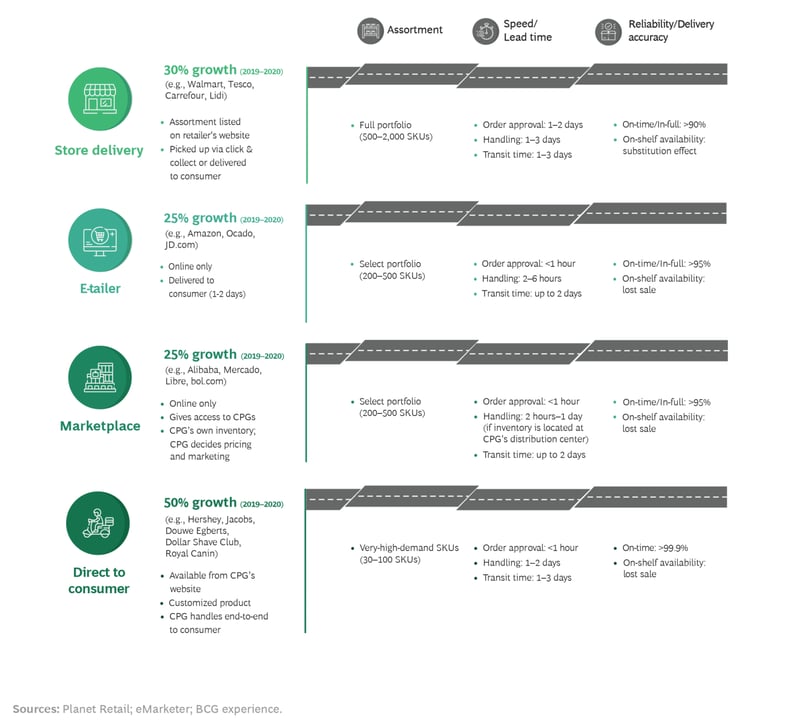

BCG proposes that rapid E-commerce growth has forced CPG companies to contend with segmented and distinct supply chains that balance assortment tradeoffs, lead times for order fulfillment and transit, and delivery capabilities against maintaining market presence. The exhibit below expands on this.

Rapid E-commerce Growth Created Challenges for All Four Channels

Another trend we at IL2000 saw firsthand is the acquisition of competitor companies, which necessitates strict transportation management to ensure the supply chain continues to operate end-to-end. Careful focus on OTD and standardization across distribution centers to harmonize rates and carrier compliance are also areas for optimization.

Moving ahead

Times are a-changing, and so are CPG supply chains. Here are some tips to consider to ensure agility and performance:

- Consider brand portfolios to balance cost, production time, and transportation against demand. Supplying the right product in the right place at the right time can be a balancing act of epic proportion. Getting only one aspect right is not enough. Turn to data insights and BI dashboards to understand performance and to see where, and more importantly how, to improve.

- Understand the role supply chain functions play in what used to be a simple supply and demand equation. Constant fluctuation in demand across multiple channels necessitates that companies revisit their planning and requirements often. As a result, strategy may become shorter-term while assumptions are overturned and new growth plans put in place.

- Focus on agility and streamline costs by reducing the complexity of your product offering. Simplifying will also help enable flexibility and resilience.

- Reconsider your transportation model. As brick-and-mortar businesses become predominantly online and consumers expect products delivered to their house within hours, and still retail customers want well-stocked shelves, CPG companies may need to partner with a 3PL to rethink their logistics model. Reconfiguring inbound and outbound shipments, drawing new distribution models, and contracting compliant carrier fleets with a good reputation for on-time delivery will help companies build and maintain strong reputations while reducing costs and growing profit margins.

If you want more in-depth examples of how a 3PL can help CPG companies manage supply chain challenges, don't hesitate to get in touch with us. Otherwise, coffee break over – so put your Maxwell House coffee, your Shamrock milk and your package of Oreos away and get back to work. Which reminds me, if you love coffee, you might enjoy this blog: Coffee, logistics, and the importance of big steel boxes.