JIT: Here are three letters that can strike fear into the heart of even the most seasoned supply chain manager. This jittery little acronym refers to the “Just-In-Time” delivery model, a unique and exacting approach to supplying a production line with exactly what it needs at exactly the right time.

The upside of JIT? By not arriving early, the manufacturer neatly sidesteps hefty warehousing costs; by not arriving late, production can blaze on at optimum efficiency. The downside? JIT is a logistical tightrope act with no safety net and a long drop. There is no margin for error.

This blog post is about that long drop, the precarious balancing act of just-in-time delivery, and — most importantly — how IL2000 can help you make it work.

But first, let’s talk about logistics, life, and death.

A tale of logistics, life, and death

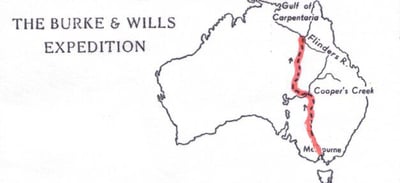

A century and a half ago, much of Australia’s interior was just a big black spot on a map. All Europeans could say for sure about the continent’s hellish interior was that it was hot, dry, and deadly. The Victorian Exploration Committee (a rough equivalent to Britain’s Royal Geographic Society) thought it might be wise to get a bead on this strange new country’s innards, so they commissioned a party of adventurers to cross the continent on foot. Two men were chosen to lead this dangerous expedition — Robert O’Hara Burke and William John Wills. Departing from Melbourne in the winter of 1860, they led an expedition of 19 men north to the Gulf of Carpenteria, a distance of roughly 2000 miles.

A century and a half ago, much of Australia’s interior was just a big black spot on a map. All Europeans could say for sure about the continent’s hellish interior was that it was hot, dry, and deadly. The Victorian Exploration Committee (a rough equivalent to Britain’s Royal Geographic Society) thought it might be wise to get a bead on this strange new country’s innards, so they commissioned a party of adventurers to cross the continent on foot. Two men were chosen to lead this dangerous expedition — Robert O’Hara Burke and William John Wills. Departing from Melbourne in the winter of 1860, they led an expedition of 19 men north to the Gulf of Carpenteria, a distance of roughly 2000 miles.

The expedition was a life-or-death logistics puzzle.

The expedition team filled six wagons with enough equipment to keep 19 humans, 23 horses, and 26 camels alive for two years. Unfortunately, it seems that the make of wagons they used was the Ford Edsel of its day, and three broke down before they got out of Melbourne.

Still, they pressed on. By the late 1860s, the adventurers set up a depot camp at Coopers Creek, the farthest point any European had explored. Supplies were running low. The blazing heat of summer was fast approaching. In a few months, the desert would be a wasteland of dust, flies and death. They took stock of their situation and decided they had just enough time to make it to their destination before the heat became deadly. But time wasn’t on their side. They had to move fast.

Still, they pressed on. By the late 1860s, the adventurers set up a depot camp at Coopers Creek, the farthest point any European had explored. Supplies were running low. The blazing heat of summer was fast approaching. In a few months, the desert would be a wasteland of dust, flies and death. They took stock of their situation and decided they had just enough time to make it to their destination before the heat became deadly. But time wasn’t on their side. They had to move fast.

So they hatched a plan — equal parts brilliance, bravery and bull-headedness.

Burke and Wills would travel light and fast, setting out north with a horse and barely enough supplies to survive the four-month return journey. The rest of the team would form a crucial link in a do-or-die supply chain, maintaining just enough supplies to replenish the returning explorers and — hopefully — get everyone home.

It was a mad dash to the finish line.

If everything went perfectly it could work, but everything had to happen just in time. Burke and Wills needed to get back just in time to beat the dry season and death from thirst and starvation. The depot camp had to set a precise departure date so they could make the long journey home just in time to keep everyone alive with their rapidly diminishing supplies. It all boiled down to a string of life or death supply chain decisions, and it all had to happen just in time.

Four months came around. Burke and Wills hadn’t returned. The depot broke camp and left, barely making it out with their lives. Just nine hours later, Burke and Wills limped back into camp. They missed their chance by just nine hours, but it may as well have been an eternity.

Both men met their fate out there in a brutal and unforgiving desert.

The JIT balancing act

The precarious balancing act of just-in-time logistics is nothing new, and thankfully the stakes these days aren’t quite so high. Whether your client’s production lines rely on materials arriving at just the right time or your manufacturing does, your continued success rides on a bulletproof supply chain. Sure, there are fewer flies and dingos, but there’s still no margin for error.

Here’s where IL2000 comes into the picture. We work with companies to make just-in-time delivery a viable and secure approach to supply chain management.

Check out this JIT case study for a window into the great results we’re delivering.

Interested in what we can do for you? Here are some of IL2000’s key value-adds as we work with you to walk that razor-thin logistics tightrope:

1. We help you choose the right carriers and shipping lanes Just as our intrepid explorers might have made different decisions if they had a three-week stockpile of rations up their sleeve, a company with a more relaxed supply chain can afford to choose cheaper carriers with slightly lower reliability.

Just as our intrepid explorers might have made different decisions if they had a three-week stockpile of rations up their sleeve, a company with a more relaxed supply chain can afford to choose cheaper carriers with slightly lower reliability.

When managing a JIT supply chain, you have to balance cost and reliability differently. We work with companies to optimize their shipping lanes to prioritize unassailable reliability. We'll also customize your TMS environment to help you dynamically choose carriers that fit your risk profile.

Thanks to upgrades like these, JIT clients see sharp increases in on-time performance (OTP) and greatly reduced losses from mishandled shipments. These efficiency gains may even decrease overall shipping costs despite paying for greater reliability.

2. We help you react quickly to the unexpected

Imagine how differently the Burke and Wills story would have gone down if the explorers could radio back to their base camp. If only CB radios were a thing in the 1860s! Burke and Wills could have asked for help and the history books would have been graced with one more happy ending.

Think of our supply chain rapid response team as your logistics base camp. If something goes wrong with a shipment, in under 15 minutes one of our experienced supply chain specialists will be crunching the numbers and finding your solution. Decades of experience in supply chain management are on call to help you move swiftly from a problem to a successful outcome.

3. We help you know what’s going on

At every point of their journey, our explorers were slowed down by a lack of information. When a new mountain range or gulley appeared on the horizon they had to spend precious hours on painstaking reconnaissance. What if they could whip out their smartphone and google a map?

We offer the modern-day supply chain equivalent. IL2000’s power BI dashboard equips you with an accurate, real-time picture of exactly what's going on across your whole supply chain. Need to see hour-by-hour updates on a critical shipment? We can have reports in your inbox like clockwork. Or let's say you're dealing with an extremely complex shipping lane. IL2000 can link up your BI dashboard to our team of logistics advisors. A seasoned logistics operator can be notified and actively helping you troubleshoot a shipment problem in just minutes.

4. We help you design and build key distribution points

If only our doomed explorers had just one more supply point along their perilous journey. They’d have been able to control the variables more effectively and recover swiftly in response to the unexpected.

If only our doomed explorers had just one more supply point along their perilous journey. They’d have been able to control the variables more effectively and recover swiftly in response to the unexpected.

Today, just as 150 years ago: Distance kills efficiency. IL2000 can help you conquer the tyranny of distance. We’ll work with you to identify the right locations for additional distribution centers both in the US and overseas so that you can reliably get your product to where it needs to go, exactly when required. There’s no big black spot on our map.

A new distribution center was a game-changer for our food packaging client, who was able to guarantee same-day delivery to one of their largest customers. They blew past anything competitors could offer and gleefully went after a wealth of new growth opportunities.

Blaze a trail and make it just in time with IL2000

You may not literally be trudging through a snake-infested heck-hole with just a few precious hours left to make your mark on history, but still, making JIT work is hard! Especially if you’re going it alone.

So… don’t.

Invite IL2000 to join you on your daring supply chain expedition. IL2000 can help you build a bullet-proof supply chain. We’ll keep your profitability safe with rock-solid reliable carriers; business intelligence omniscience; and a resilient, well-distributed supply chain.

When time matters, don’t leave anything to chance.

Reach out to IL2000 for a no-obligation JIT-readiness analysis.