We saved a company over $100k on one (incredibly problematic) freight claim

In our last situation file, we looked at a typical freight claim negotiation. Let’s now dig into a much tougher scenario. What do we mean by “tough,” exactly?

This freight claim had all the incendiary ingredients for fraught negotiations. The question of liability was filled with shades of gray. Lots of money was at stake. Key players distrusted one another. Basic facts were in dispute. Emotions were running high.

We could throw in a few more scarily punchy sentences here, but you get the feel of the deal. The situation was a supply chain problem dialed up in intensity to 11.95 recurring. It’s not all doom and gloom, though, because we’ll also show you how IL2000 ended up resolving the situation while saving our client easily six figures on just one shipment.

The upshot

- Tough and heated negotiations brought back from the brink of collapse

- Over $80,000 in shipment value regained for our client

- Over $20,000 in needless freight costs avoided

The sitch

First up, a complexity alert. The context for this one is detailed and multifaceted, so strap in.

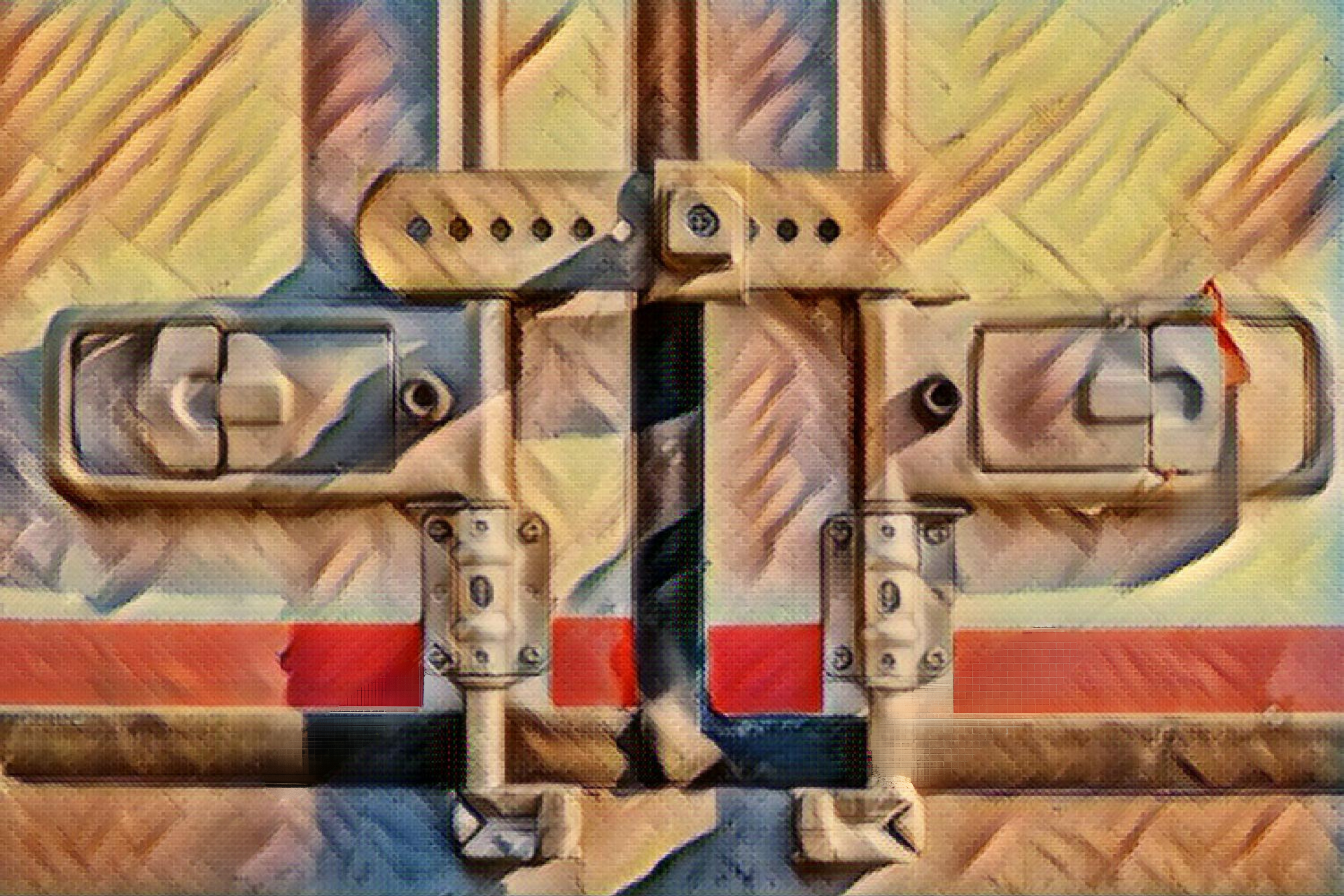

Our client received a large and expensive shipment from a vendor to one of their warehouses. This was a dedicated truckload of food-grade materials, so our client instructed the shipper to seal the loaded truck with a tamper-proof plastic lock.

When the driver arrived at the warehouse, the seal wasn’t affixed to the door. The driver said the seal was never put on the truck. The shipper said the seal had been put on the truck. Our client refused the shipment, paying an additional exorbitant shipment fee to send everything back.

Differing accounts flew back and forth, and that flurrisome furor soon transmogrified into sullen accusations. Our client, the shipper, and the carrier were all angry. Communications broke down (if that last bit weren’t clear enough already). Exacerbating these mounting tensions, no one could accurately pin down culpability, let alone legal liability.

It was here, amidst a situation murkier than day-old dishwater, that our client had no choice but to submit the grumpy grandmother of all freight claims.

What was going wrong?

- Impulsiveness: OK, we’d run out of fingers if we pointed them in this situation, but let’s just say people (being people) acted rashly. The shipper and the carrier could have double-checked the seal was in place before hitting the road. Our customer could have accepted the shipment and resolved it from their warehouse.

- Antipathy: Exactly what happened was hard to pin down. When mistrust and opposition crept into the equation, the problem became as much about personalities as finding a satisfactory resolution.

- Intransigence: A lot was at stake here. Quarterly profits might have taken a beating. The carrier may even have gone under had they been found at fault. No one was prepared to budge much more than a sixteenth of an inch (1.5875mm).

The solve

If we laid out every step of what happened next, we’d be dealing with the blogging equivalent of a sweeping twelve-part telenovela narrated by Morgan Freeman … so forgive us if we truncate a smidgeon.

When we entered the fray, the first thing we did was slow the conversation down. We listened. We collated all the available information to assemble a detailed picture of the events from every available perspective. We asked the right questions and backed each step up with calm and impartial analysis. That brought focus back to the facts and reopened productive dialog.

Another big part of this was the legal dimension.

Liability was gray in this case because the absence of a seal does not mean damage. In theory, the carrier could just walk away. Legally, our client had to prove damage or contamination. Without that proof, no one was obligated to pay anything for this freight claim.

It was a tricky balancing act. At one point, the carrier went quiet… too quiet. Discussions looked set to grind to a standstill, so we asked our internal carrier contact to help out. Our rep has a longstanding relationship with key people inside their company, and we were able to restore lines of communication.

As you can imagine, all of this took time.

But our team has clear heads for this kind of work, and finally, we were able to establish (and prove) one crucial detail. The security seal was with the truck, but the shipper hadn’t used it. Whoever loaded the truck clearly meant to but forgot. After ruling out conspiracy theories, shady practices and coverups, we were left with a rather boring but remarkably neat conclusion.

It was all an innocent mistake.

It sounds like such an obvious closing point to the negotiation laid out like that, but it took many conversations to get there. Our facts-first approach had simmered tensions to the point that all parties were ready to see the incident not as some intractable catastrophe but as one unfortunate event that could, with enough elbow grease and introspection, be fixed.

And what did that resolution look like?

Well, we helped get the freight back to the shipper so that it returned to their inventory. Our client gained their refund, and the carrier continued to support this supply line. So it was business as usual, with no lasting harm … OK, but with a few key action items uppermost in everyone’s mind to make sure it didn’t happen again.

We also played a role in prevention.

We talked to our client about what they could do differently next time to get a faster, better, less-ulcer-inducing outcome. We also bolstered our client’s relationships with the carrier and the shipper — both of whom, at the end of the day, were great operators staffed by occasionally fallible humans.

The supply chain equivalent of the Sharknado movie franchise (worth catching if you have 40 hours and a few million brain cells to kill) had blown over to little more than a situational storm in a truckload teacup.

What went right?

- Persistence: In any difficult negotiation, people sense persistence. IL2000 wasn’t prepared to let the carrier or shipper ignore our client’s concerns. As supply chain consultants and partners, we advocated on their behalf and kept communication lines open.

- Influence: Our reps have longstanding relationships with carriers. When negotiations got stuck, we applied leverage from a different angle.

- Experience: The only way this situation could end well was with a win-win, but finding that balance didn’t come easily. It took an experienced team to take an incendiary situation and transform it into an evidence-based outcome everyone could accept.

The take home

Supply chain mistakes are easy. They happen innocently and accidentally. Supply chain solutions usually take work. They’re built on hard-won industry experience, careful fact-gathering, and trust. Oh, and patience. Lots and lots of patience.

If you’re looking for real answers to seemingly intractable supply chain problems, we can help. Start a conversation today.