We have a short ’n sweet blog for you this week. We wanted to explain IL2000’s continuous improvement process — the process by which we help our customers systematically improve the operational efficiency and overall resilience of their supply chains through strategic managed services. Now we could wax lyrical about it, sure. We could build in a snazzy metaphor from Ancient Sparta, drop in a few pithy examples and reconvene in a couple of thousand words for tea and crumpets.

But meh. It’s June. It’s sunny outside.

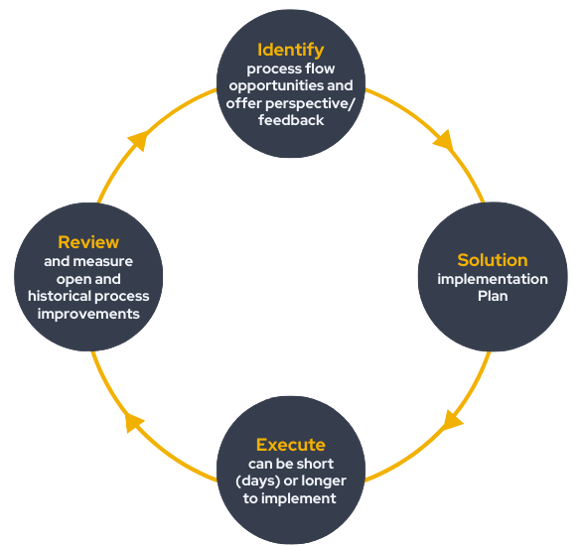

So how about we all take an early mark this week and sum up the whole shebang, a cornerstone of supply chain management, with a handy dandy diagram? Let’s see, a quick copy and paste should get that diagram in here …

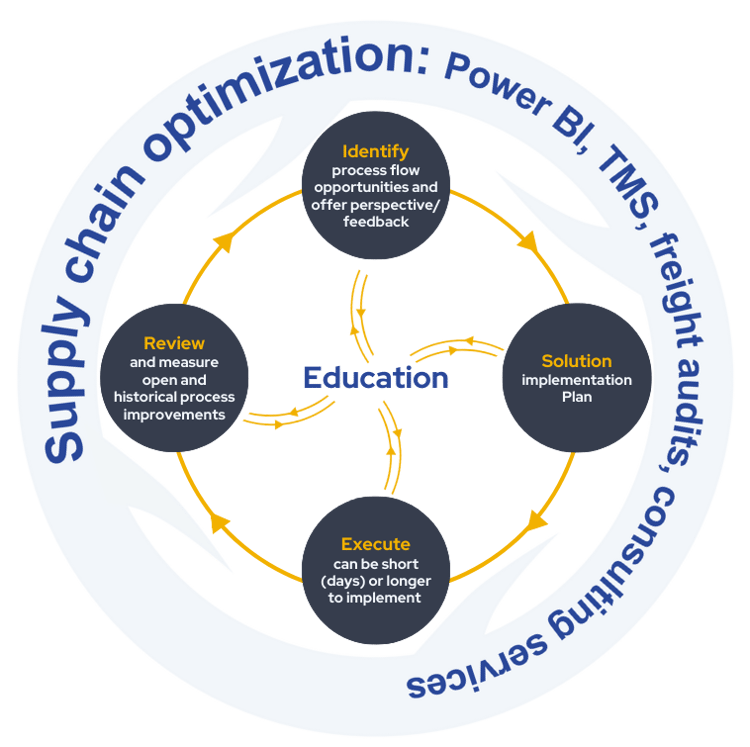

… and voila. Neat as a pin. So what are we saying here?

We’re saying that our continuous improvement process is built on four interconnected processes. We continually identify opportunities, formulate solutions, carefully execute those solutions based on an agreed plan, and then review our results so that we can collectively refine our customers’ supply chain workflows. Paired with increasing supply chain visibility, we get meaningful results.

And there you have it! This is our continuous improvement process. Thanks to the combined miracles of coffee and Canva, we can convey a key message about our work with one simple graphic. And we didn’t even have to talk about Ancient Sparta.

Enjoy that beautiful weather, and tune in next week when we’ll solve world hunger.

Oh, wait…

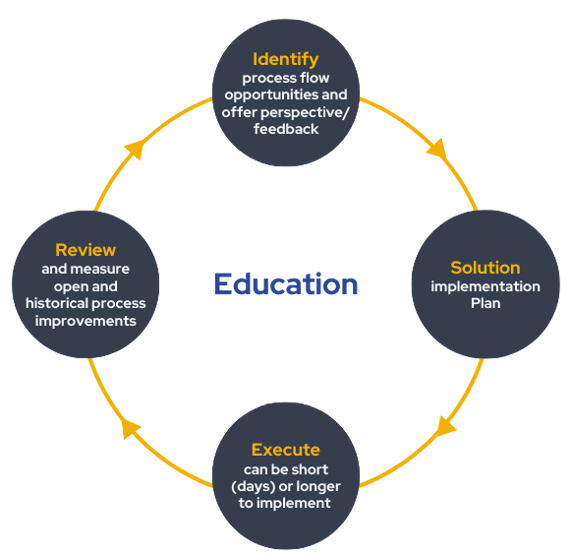

Hmm… except that diagram is missing something important. OK, one quick modification and we can blow this popsicle stand.

Yeah, anchoring the word education in there is important because all of those processes — identifying, solving, executing and reviewing — they all depend on a solid flow of knowledge and education between us and our customers.

We’re constantly showing our customers how better to use the tools we build for them, from the daily practical operations they perform through our TMS to the deep dive analyses they can perform through Power BI.

That knowledge flow is integral to everything we do.

But shoot, we missed something important…

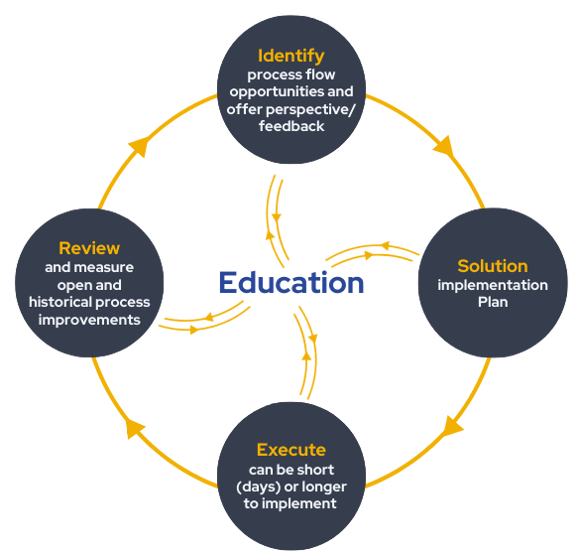

Ugh. But that’s still not the whole picture either. We’re not just spamming out knowledge to our partners like some demented, wild-eyed, cave-dwelling supply chain oracle. The continuous improvement process we engage in with all our customers is a dynamic and flowing two-way street of information.

It’s a conversation.

Layer 3 coming up:

Ah, that’s better. The arrows here show that we educate you, and you educate us. Customer satisfaction is a two-way street, requiring learning on both sides. This is core to gaining a competitive advantage and overcoming the clear supply chain challenges in operations. These are no pie-in-the-sky arrows, either. The flow suggested by this veritable cornucopia of pointiness tracks closely with how our company is internally structured.

Actually, we can go one better. It tracks closely with how we collectively think.

We aren’t siloed. All our experts talk to each other, share ideas, and formulate improvement strategies that take a multiplicity of angles and opportunities into account, creating true relationships as part of our strategy to supply chain consulting.

We aren’t inward-looking either. We assign a pod of supply chain advisers to each and every customer. That team’s job is to gain a comprehensive understanding of what our customer sells, how they shift it from A to B, along with the many broader variables that impact their daily freight operation.

You won’t believe this, but…

…we’re still not quite capturing it.

I mean, look at this thing.

Here we are in abstract space looking down at an internally cohesive swirly thing of interconnected ideas, but … ugh … what does it all actually mean? Right now, this diagram thing is just a corporate thingamajig. It’s some pleasing little teaser PowerPoint slide before we get to the important stuff with line charts and dollar figures.

No. That's not what we mean at all. We're not squandering this beautiful June afternoon for … for … a bit of banal business bling. Continuous improvement means more than that to us.

That process up there with all the circles and arrows and whatnot — if you set it up right, it’s a dynamo of change in your supply chain. It has weight. It throws out energy. It imparts momentum and stability to your supply chain operation.

Less prosaically, continuous improvement saves you money. Real money! It saves you time. Tons of it. This process helps your supply chain stay robust and resilient. It keeps your company happily profitable when your competition is flailing and falling by the wayside.

To really convey how continuous improvement really works, we need to really bolt this puppy right into your freight operation’s engine room. Here’s what that might look like. Ahem, really.

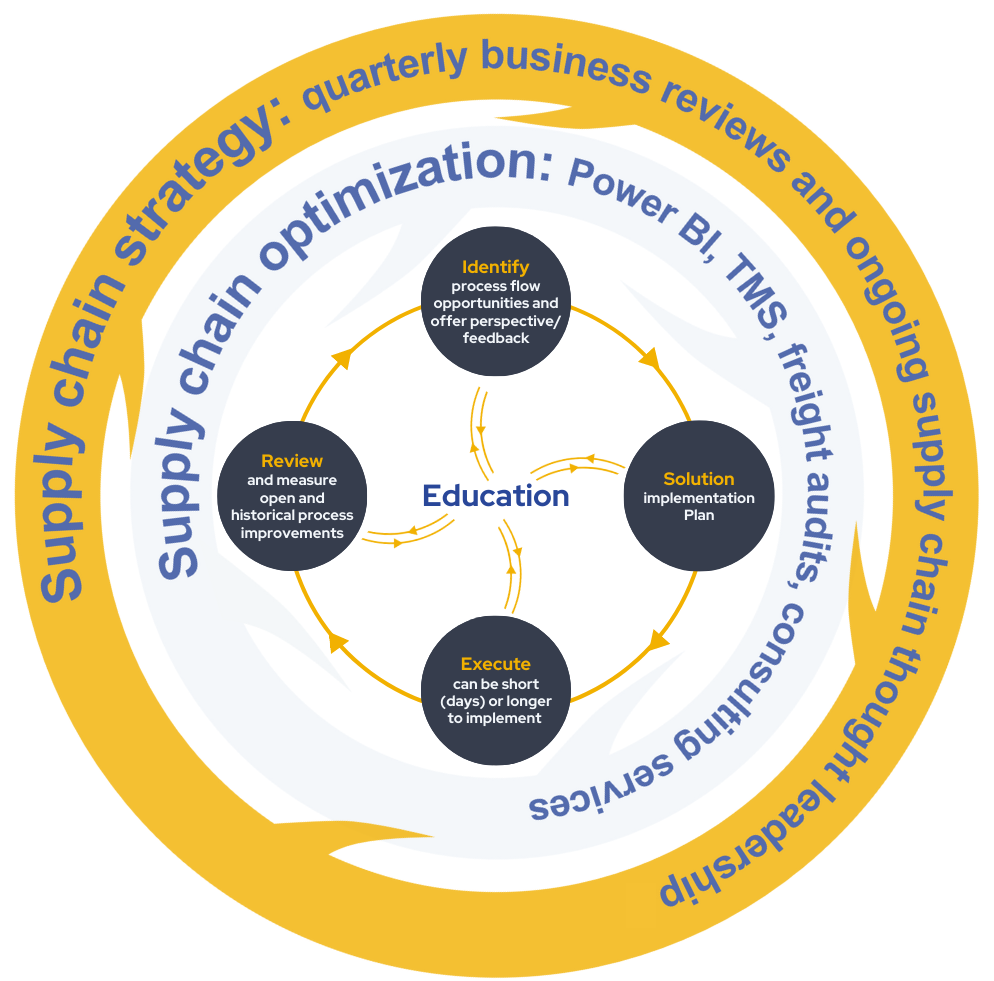

OK, yes, at this point of diagrammitization (not even remotely a real word), things get a teensy bit abstract.

But the point we’re trying to make here is that all this supply chain improvement machinery we build with you actually does something. That knowledge ripples out across your company, and it converges around a suite of powerful tools and services: in particular, Power BI, our industry-leading transportation management system, and a stable of freight optimization consulting services.

And just like the immense body of useful supply chain knowledge we build up with you, these tools are ever-changing. We build versions of Power BI and our TMS that specifically integrate with your business. Then, as that improvement flow distills new findings, we go further and deeper.

Long story short: IL2000 will customize, tweak and continually refine these tools to more efficiently handle all those daily decision-making points upon which the efficiency of your supply chain turns.

So yeah, this diagram would be incomplete without a powerful line of causality between education, our continual improvement process, and all those daily transactional supply chain decisions that save you big money here, real time there.

And in conclusion…

Phew. So we made it there in the end. Yes, I’ll grant you, we weren’t done quite as quickly as we promised, but you now have a shiny diagram that explains what IL2000’s continual improvement process really means.

Feel free to print it off and stick it on a fridge somewhere (probably a whole door, but still).

Only — we almost hate to tell you this — but we’re not quite finished.

You see, all that transactional stuff circling around our continual improvement process — we aren’t the only company that performs these services. None of our competition’s services, we’d contend, are built on quite the same quality of intellectual machinery! But, of course, you can secure BI, TMS, and freight audit services on a transactional basis with any number of companies.

But our continual improvement process offers an additional, more strategically focused layer.

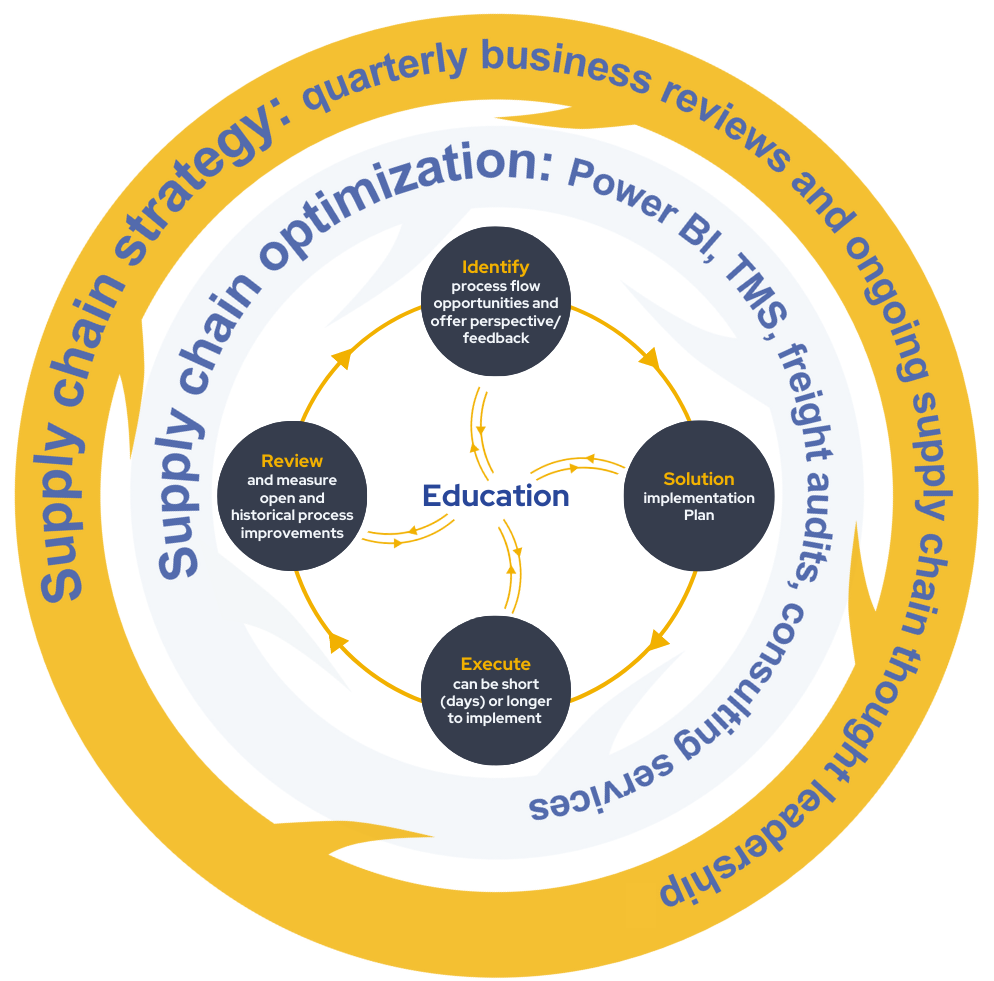

Hmm, here’s what that might look like:

What are we looking at here?

Well, for one thing, we’re looking at compelling evidence that graphic design is an extremely technical skill set and should not be left to rank amateurs. But we’re also staring at a diagrammatical representation of the fact that IL2000’s continuous improvement process doesn’t end with a set menu of transaction-based services.

There’s a deeper magic at work when we sit at your table to look at how your supply chain could better serve your company’s future.

Every quarter we sit down to conduct a quarterly business review. In these reviews, we talk about strategy. We look at what we collectively envisioned for your supply chain. We compare that to what has changed. Then together, we devise a better way forward.

It’s here, in the domain of pure thought partnership, that IL2000’s continual improvement process imparts its deepest impacts on how your company shifts its products.

The real conclusion: supply chain improvement is everywhere and based on expertise

So cast your eye from the center of our (thank goodness) final diagram outward.

- Decades of combined supply chain knowledge blend with your company’s expertise to generate a dynamically creative dialog. From problem identification to solutions to plans to analysis, your people and ours get to work. We talk. We set wheels in motion.

- And all of that coalesces around a suite of powerful improvement tools: principally IL2000’s TMS and BI dashboard. Work gets easier, and we begin to find ways to build new improvements on top of old improvements.

- Then those operational improvements begin to generate deeper swirls of insight. This is the strategic realm of continual supply chain improvement where we can consider the large-scale changes that’ll keep your company’s supply chain lean, resilient, and growing in the years to come.

So … um yeah. We’re so glad we could build a diagram to succinctly explain IL2000’s commitment to continuous improvement! Who’s up for wiffle ball?

Ready to see radical supply chain improvement? Explore the IL2000 process, and speak to an expert to get started. We even do diagrams.