Many companies feel helpless to navigate through the uncharted waters of a global pandemic and unprecedented disruption in the supply chain. What used to be clear sailing, for the most part, is now a tsunami of port congestion while the Bermuda Triangle disappears available shipping containers. Together, it’s a challenge for logistics planning in even times of minimal disruption. Shippers need a way to weather the storm.

But a company with a savvy captain and crew at the helm is not without options. The US has experienced market recessions in the past, and history shows that taking specific actions can speed up recovery and put astute wholesalers ahead of the rest.

Let’s consider the supply chain as a value network, where supplier-wholesaler-retailer work together as partners. Wholesalers play an important part in both the marketing and logistics channels. They increase product reach and help suppliers minimize the risk of selling direct to customers. They offer warehousing for various product assortments, providing both cost and time savings for companies and customers. They offer insights into customers and competition.

But what happens when massive market disruption turns world logistics into a tangled Slinky-ball of congestion? What’s to be expected when everything we’ve learned about supply, demand and consumerism begins to warp? Experts say to look to earlier times of economic distress to find the lessons that might have flown under the radar.

Lessons from previous crises

Though subtle differences exist between wholesalers and distributors, insights from how distributors navigated the Great Depression and the 2009 recession shed light on how wholesalers can emerge stronger than before.

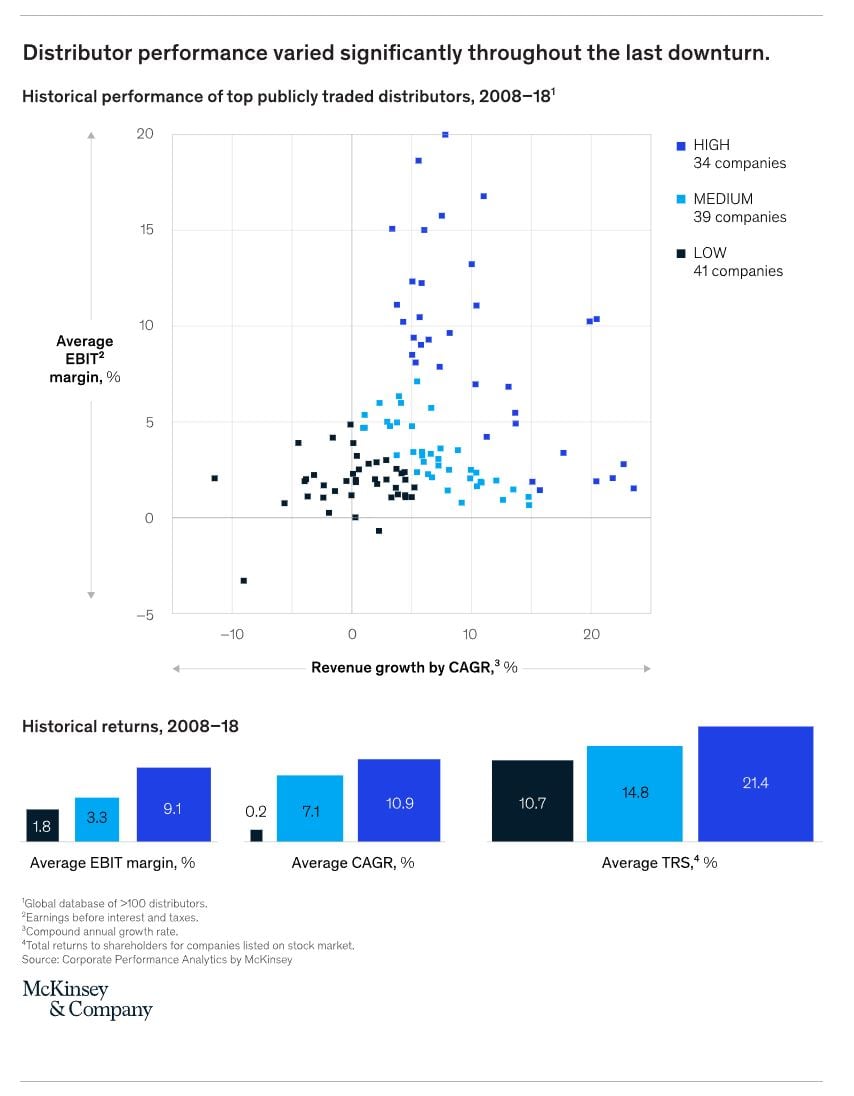

McKinsey & Company’s analysis of around 100 publicly traded global distributors showed a significant drop in revenue and margin at the height of the Great Recession. Similarly, after the 2009 recession, even when top-line growth recovered, distributors still struggled to recover the lost margins.

Though the current downturn shows similar declines in demand, consumer buying power, and stock prices as seen during the Great Depression, changes occurred much more suddenly in 2020.

To understand what factors were at play, let’s look at the performance and actions of these distributors through the previous recession. The study found that some companies increased revenues and margins faster than their peers and provided shareholders with nearly double the returns of average competitors (Figure A). How they did this becomes of critical importance as we start the year in troubled waters.

Figure A: Distributor performance varied significantly throughout the last downturn. Source: McKinsey

Looking back with eyes forward

Sounds complicated, right? To look for answers in the past without losing sight of the current environment and where you want the business to be in 6 months?

Let’s discern lessons from the high-performing distributors who bounced back the fastest.

Authorities like McKinsey say the key lies in:

- Developing a nimble cost structure. Cut costs while looking at a new organizational structure. Consider transportation management such as whether to own a dedicated fleet and team, to use carriers and vendors, or to partner with a 3PL.

- Managing cash more carefully, including adjusting inventories to reflect revenue drops.

- Diversifying revenue streams with more varied portfolios to match shifts in demand.

- Pursuing small-to-medium-size mergers and acquisitions. Impact on transportation strategies, warehousing decisions, and inventory control could lead to operational efficiencies.

Now back to today…yet again, the challenges remain.

How can we create a proactive supply chain that's not subject to inventories?

How can we define the best practices to avoid issues without necessarily repeating the mistakes of the past?

What can wholesalers do to help navigate and even profit from the current logistics snafu?

I’ll tell you how.

Set minimum order quantities and scaled pricing

Setting minimum order quantities and rewarding larger orders with a lower price per unit reduces shipping costs compared to goods sold and decreases the overall number of orders.

The operational efficiencies compound:

- Fewer orders lessen the impact on the shipping load

- Decreased shipping documentation and invoices

- Streamlined processing

- Less potential for customer inquiries

- A more efficient organization

Fewer shipments also allow more control over carrier negotiations and transportation costs, as well as reduce opportunities for a shipment to be late or delayed. Client satisfaction increases as customers receive what they need in sufficient quantities, with greater reliability.

Consider using Dropshipping

Dropshipping, or purchasing a product from a third-party supplier and shipping directly to the customer, eliminates the need for warehousing, expensive inventory balance, inventory control and asset insurance. This process frees up the person-hours that otherwise go into inventory control, shipment tracking, and handling customer returns.

Without warehouse and inventory constraints, companies can reevaluate their offering and potentially offer more products.

Work explosive demand, empty shelves and decreased demand to your advantage

Some industries have seen explosive demand for specific products. Some offer benefits, like frozen foods and dry goods that don’t spoil with longer delivery times, while others come with challenges, such as bulky toilet paper that increases inventory costs.

While retail shelves are turning up empty and consumers continue to bulk buy anticipating these shortages, wholesalers have the opportunity to evaluate their suppliers for reliability, source alternative products, and offer up solutions to their retailer partners. When it comes down to it, kids need school shoes regardless of brand, and a kitchen would be lacking without eggs – white, brown, organic or not.

What about decreased demand? Switches in product portfolios mean new supplier and retailer relationships and possibly new and unique shipping circumstances.

And how about the in-between of irregular demand? Companies have taken aggressive steps to manage costs and ration products, but many still struggle to understand the complexity of supply-chain disruptions. Often, they turn to a 3PL to help.

Supply chain management mitigates disruptions, improves productivity, and reduces costs

Logistics management focuses on the chain of processing, warehousing, inventory, and transportation. It assures the delivery infrastructure of goods from the point of origin to the point of sale efficiently and cost-effectively.

A logistics partner will handle carrier and vendor negotiations to ensure the best competitive pricing, reliable delivery, and product quality. With this control and visibility into transportation and freight costs, wholesalers can set the final product price to ensure a margin. Yes, you heard right. As long as customer satisfaction is maintained, the shipping department becomes a profit center.

An automated process and robust auditing shorten the order-to-payment cycle and improve cash flow.

Using a logistics management system that offers GL coding and works seamlessly with your Automated Inventory Management System reduces inventory pile-up, optimizes warehousing, and allows scalability. Not to mention the increased process speed with less potential for human error.

What we’re saying,

What we’re saying, and apologies for returning to the steering the corporate ship metaphor one last time, is there are tools to locate the hidden icebergs, systems to chart new courses and experts to help you arrive in port with happy customers and your profitability intact.

What does the future hold?

Unpredictability, certainly. But also, the potential for process efficiency, new transportation models and expansion into product areas unconsidered even two years ago.

The future offers possibilities. Contact a consultant to see what this could mean for your supply chain.