We’ve talked a bit lately about IL2000’s commitment to helping customers continuously improve their supply chains — the key word there being continuous. IL2000 doesn’t think of supply chain optimization as this one-and-done process where we implement a set menu of changes, and boom, your supply chain is now perfect.

Logistics doesn’t work like that. Business doesn’t work like that. Heck, change itself doesn’t work like that.

You can read more about our continuous improvement methodology, but the core idea we’re driving at can be summed up quite simply: We help our customers maintain a strong supply chain through an ongoing process of analysis, solution-building, execution, testing and refinement.

In this blog, we’ll take that idea of continuous improvement as our starting point and apply it to the more strategic end of what we do, and in particular, our quarterly business review (QBR) process.

Why haven’t we mentioned QBRs before?

The thing is, we have talked about the quarterly supply chain business review process throughout our blogs — quite extensively even. But QBRs are somewhat hidden in plain sight. We tend to talk more about what they deliver, including analysis of our customers’ expectations and results, than the review process itself.

For example, you’ll find QBRs referenced obliquely in the great majority of our case studies.

- Here we talk about how we helped a packaging manufacturer harness its data to better identify future supply chain challenges.

- Here we talk about how we helped a building products manager build a more agile supply chain in a competitive marketplace.

- Here we talk about how the QBR process helped us identify and then build better supply chain tools for a rapidly expanding auto parts manufacturer.

Any time we talk about IL2000 coming alongside customers to help ideate long-term supply chain objectives, QBRs will have played a key role in making it happen.

Here’s the tip of the QBR iceberg:

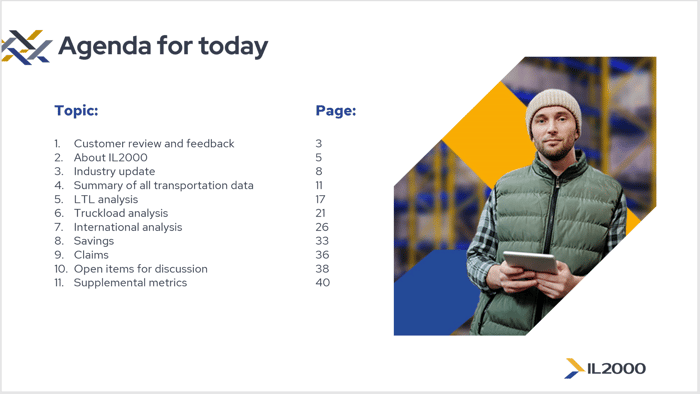

What does a QBR actually look like? Well, maybe the easiest way to tackle that question is to show you a typical table of contents from an actual QBR we conducted:

What’s going on here?

- First, we talk about the last quarter. We ask our customers for feedback about their supply chain; then we give a quick recap of how IL2000 has helped them over the period.

- Then we dive into a conversation about our customer’s industry and sector. What’s new and emerging? Where are the pain points? Where are the opportunities?

- From there, the real deep dive begins. We work through the customer’s supply chain data from every conceivable angle, including LTL, truckload and international.

- This will lead us naturally into a conversation about what’s working and what isn’t from a data standpoint. What savings are being missed? What claims are happening? How do we fix those problems while forging better carrier relationships?

- Everything coalesces in a “what next” conversation where we identify action points, timebox each step, and define what the customer’s overall supply chain strategy now looks like.

So, data! Lots and lots of data. We won’t rehash all of that data stuff here, however, because we’ve talked about it at length elsewhere.

- Here’s our Director of Enterprise Account Management talking about how clear ideas win customers.

- Here’s our Director of BI and Reporting talking about the true meaning of data.

- Here’s our Director of Pricing talking about the data deep dive and how good data dissolves fuzzy thinking.

Humans have entered the chatroom

Glance through that table of contents and you might be tempted to think that this is purely a freight data conversation, that the only people in your company who'd have anything to contribute are "data folk" — the people who own and maintain the endless array of freight checklists and paperwork and spreadsheets.

But squint with us for a moment at all those ones and zeroes. There! See that warm little glimmer? All that business reviewing we do nigh on every three months? At the end of the day, it’s about warm, squishy humans.

There’s a reason our QBRs happen face-to-face:

- Fuel consumption charts aren’t the same as trucks and drivers and rain-slicked highways.

- Center of Gravity analyses aren’t the same as labor availability, distribution warehouses and the oppressive weight of corporate history.

- On-time-delivery pie charts aren’t the same as satisfied customers and a sane and stress-free workforce.

Data should facilitate the planning conversation, sure, but it shouldn’t limit where it can go. Here are a few examples.

The case of the wrong sticker

We were onsite with a client talking about on-time delivery. Their chart was healthy, but there was a disconcerting little dip in data in the previous quarter. The client explained that a carrier had repeatedly failed to identify priority shipments. It was puzzling.

A member of our review team with decades of warehouse management experience asked to see the packages that weren’t making it in time. A tiny, white sticker timidly proclaimed the package’s priority status with a tastefully low-key font.

We made it red. And doubled its size. And repositioned it so the carrier couldn’t fail to notice it. And just like that, the problem was solved.

The conundrum of the overcharging carrier

Another customer. Another quarter. This time our customer observed unexpected up-charges on packages going out from one distribution center. We dug deeper and saw that the carrier was revising weight estimates for these packages.

A bit of sleuthing onsite revealed that our customer had been using weight estimates on difficult-to-weigh packages. We advised on suitable scales and helped set up an improved weight estimate workflow. Instantly, the problem disappeared. Deliveries arrived at their destinations faster. The company was able to budget freight outlay within an appropriate margin of accuracy and save on carrier-charged reweighs. At the end of the day, time and money were saved.

Again, the problem looked intractable and mysterious right up until the point that we set the graphs aside and investigated what was happening in the trenches.

The mysterious matter of humans themselves

And then there’s just the indefinable human element. People, as a general rule, are really not that great at speaking up and being clear and direct with one another. With a video-mediated conversation about spreadsheets and data it’s all too easy to just steer clear of those many practical supply chain challenges.

In isolation, they may not be much, but add those missed opportunities up and you end up with a slew of needless efficiency bottlenecks.

When you’re in the same room, these conversations tend to happen. And this can pave the way for clearer thinking, better solutions, and ultimately, more effective supply chain strategy.

We work to provide real, agile supply chain solutions

Our Director of Enterprise Account Management, said it best:

“It's such a great feeling to get in front of the clients, work with them, talk with them, meet different departments, understand their business needs, understand their goals. We work to provide solutions; they may be small or large-scale, and they may take weeks or even a month to analyze and bring to the forefront, but the result of the hard work is motivating and builds trust.”

Smart, forward-looking supply chain strategy doesn’t come solely from data. We build good strategy from conversations, from shared perspectives, from ingenious and creative partners sitting in a room and getting their heads together.

Talk to IL2000 today about how quarterly business reviews can transform your supply chain.