Part II

Welcome to part two of our blog series about how IL2000 can help you make big logistics outcomes happen with a comparatively small but hyper-efficient outlay of time, money, and effort. If you haven’t read part one, check it out here.

In this blog, we’ll shift our focus to the challenge of geographical distance and how you can efficiently scale your freight operation to overcome it. Then we’ll talk about people and how crucial it is to access the right experts at the right time.

But first, we’ll quickly reprise this idea of a supply chain “fulcrum.”

The gist revisited

Archimedes said, “Give me a lever long enough and a fulcrum on which to place it, and I shall move the world.” What we’re saying is, you can get a lot more done if you find the fulcrum points in your supply chain operation. There are perfect points of leverage in the complex jumble of things you do to keep your products moving. Your challenge is to find them. And our job at IL2000 is to help make it happen.

Breaking that down a little:

Let’s say you’re a Director of Logistics…

and you’re looking for a smarter way to run your supply chain. Using a conventional approach to supply chain optimization, your company will likely employ a range of incremental improvements — things like a generic TMS package, freight brokering, or rudimentary freight auditing. There’s a good chance you’ve already gone down that road.

Here’s the problem with that conventional approach

You’ll rapidly hit the law of diminishing returns, where additional outlay on conventional supply chain improvements will cease to deliver meaningful returns. While none of these measures are inherently useless (well, OK, that generic TMS package might be), none are game changers either.

Here’s how IL2000 does it better

Drawing from decades of experience, customized BI and industry-leading management tools, we can show you how to achieve significant supply chain outcomes in a cost-effective way. It boils down to applying the right intervention at the perfect place and time.

Case in point: In our first blog, we looked at your first two immovable logistics constants – time and weight. We showed you that IL2000’s TMS is a powerful time productivity force multiplier. Through companywide integration and deep customization, we can win back hundreds of hours of productive time for you across all your departments. We also looked at weight, size and density in freight cost calculation and demonstrated that our unique approach to freight auditing, coupled with expert technical advice, can equip you to inject cost-efficient practices into every single shipment.

Fulcrums for the win.

Introducing your next two immovable constants

Distance and human resources

So here we are, and things are looking rosy. We’ve established that, together, we can master the relentless pace of logistics time management and the relentless complexity of freight calculation — high five.

But don’t put on your comfy TV-watching pants just yet because the unstoppable force of your logistics efficiency is yet to encounter two more (seemingly) unmovable objects. We’re talking about distance and human resources…

Prepare to fall off your chair.

We have a lever and fulcrum for these problems too.

Distance: Find the shortcuts

The tyranny of distance. Humans have been ruminating on the frustrations of getting stuff from A to B at least since explorers were scratching their heads and wondering what lay over the next mountain. Dealing with distance is hard. Roads and railways don’t make anyone immune from the simple inescapable fact that the further something has to move, the more difficult and expensive it will be to get it there.

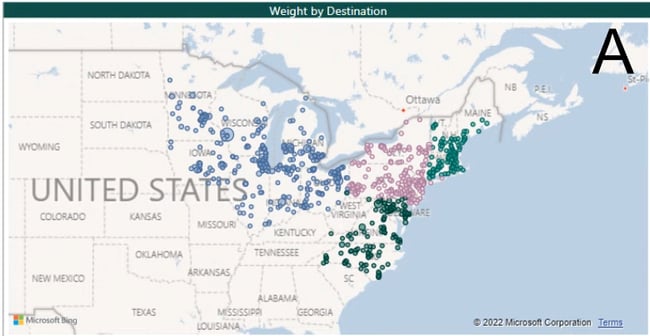

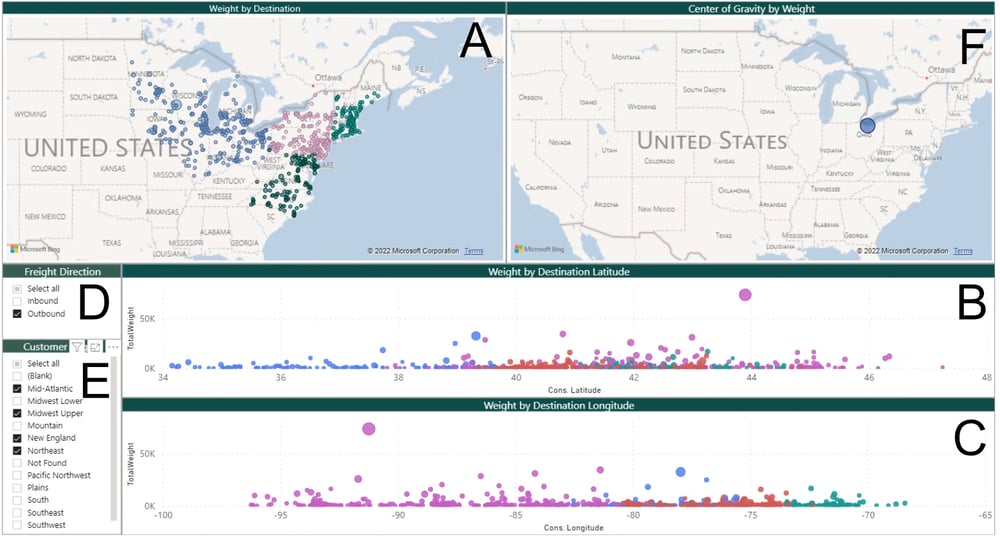

Picture a map of the US. One dot is you. A sea of other dots represent your customers, both near and far.

The more geographically dispersed those customer dots are, the more complicated your supply chain needs to be – and the more effort, money and time you’ll spend making transportation happen. A conventional 3PL approach to countering the tyranny of distance is simply to look for reasonable carriers and to shave off freight inefficiencies to the greatest extent possible. But using these simple strategies alone, you’ll always be dragged back down to that entropic baseline we talked about in blog one. Sooner or later, a big old diseconomy of scale will smack you right in the face like the proverbial dead fish.

So why don’t companies just flip the geographical script? Why don’t they conquer the map with a shiny new distribution center? Why aren’t they busily batching up their shipments more intelligently and efficiently? Why don’t they just optimize their shipping lanes to chew up more miles with less cash?

99% of the time, they lack the data.

Or, more accurately, they lack the tools, insight and expertise to capture and read their data confidently enough to fix their distribution challenges.

The fulcrum we offer to change this equation for you is our deeply forensic approach to BI and, more broadly, all things related to logistics data analysis. The rigor with which we capture and use supply chain data could be a blog in itself. Actually, what am I saying? It is a blog in itself. But the crux of the fulcrum — the humming heart of our distance-busting force multiplier, if you will — is that good BI works like an operational X-ray.

We can use BI to gaze right through the complexity of your supply chain map to identify the trends, truths, and transportation traps a human (even one with a ton of common sense) won't see.

Case in point. Remember all those dots?

We’ll grab that data and lean into a detailed center of gravity (COG) study to identify the most efficient ways you can reach your paying customers.

As we describe in full here, a COG study is important because it helps you get past what your gut instinct is telling you. It’s a powerful way to compensate for your logistics outliers, carve up your data in a multiplicity of ways, and perhaps most importantly, to explore and compare a wide range of distribution scenarios.

Ultimately, we’ll use BI to help you think differently — linking your geographical supply chain decisions to how you want your company to grow.

People: The power of having deep expertise just a phone call away.

Your other immovable obstacle is mental bandwidth.

Let’s say a hurricane is barreling its way to your manufacturing facility and you have just shy of 48 hours to prepare your freight operation to minimize damages and disruption. (It happens.)

Or let’s say a flurry of resignations of key positions in your logistics team put you into freight operations free-fall. (It too happens.)

Or here’s another one. You were working with a standard 3PL who egregiously under-delivered. This particular 3PL promised miraculous results if you bought licenses to their whizbang TMS which looked suspiciously like an earlier package you were using, only with prettier graphics. Those miraculous results never materialized, freight invoices are piling up, and your customers are beginning to send angry emails. (Yup. You guessed it, it happpppppens.)

There’s plenty you could do in each of these situations.

But you have only so many brains you can direct at the challenge. Moreover, those brains are not at their best. They haven’t done this before. They’re worried about their own homes, jobs, and reputations. They have only so much time and energy and passion to give.

So what do you prioritize?

The swirl caused by these kinds of mishaps might be fine if they were rare occurrences, but let’s be real. Supply chains are inherently volatile. The global supply chain roiling above us all is that volatility on steroids. Stuff like this happens all the time. Supply chain management is the science and art of constant course correction – of endless adjustment and counter-adjustment.

If you point a typical 3PL at these kinds of problems, their goal will be to respond to your immediate problem as best they can and to get paid. This is a transactional relationship. The problem with this approach is that it fails to address the larger business problems underlying your supply chain’s volatility.

A hurricane, en masse resignations, a busted TMS — the one thing each of these (and a raft of similar supply chain challenges) share is that you can address the symptom or focus your gaze upstream to the deeper factors at play. This upstream gaze is what makes IL2000 … well, IL2000. Moreover, because we’re supply chain experts with decades of experience spanning every corner of supply chain management, we can see systemic solutions a basic 3PL or a freight broker won’t identify.

Again, the unique perspective our expertise brings to bear could be a blog in and of itself. (And again, what am I saying? It is.) However, the bottom line here is really quite simple.

Supply chain problems aren’t solved with software. They’re solved by people.

Supply chain problems aren’t solved with software. They’re solved by people.

The people who power IL2000’s work offer a unique problem-solving perspective on complex supply chain challenges. To quote our CEO, Techa Pacitto: “Everyone at IL2000 is a problem-solver. We all have this mindset that even the toughest problems are waiting for a smart solution. Beyond expertise, I think we bring this unique intellectual courage and fortitude to the table.”

And, ultimately, that’s the pivot on which all of IL2000’s services turn. Working with IL2000 means you’re working with a team of smart problem-solvers who are passionate about getting your supply chain to run as efficiently as operationally possible.

And just like that, we’ve come ful(crum) circle

About 3000 words of bloggish goodness ago we started with a simple-ish idea:

“There is this magical point of contact — a perfect place and time and angle of impact — where just a little bit of force produces massive outcomes.”

If you never see the bottom of your supply chain’s in-tray… If you feel buffeted by unexpected carrier charges, pressing deadlines, and the eternal challenge of trying to scale efficiently in the face of unprecedented supply chain volatility … you may be left thinking the only answer is to push just a little bit harder.

But you can only push so hard and for so long.

There’s a better way to make logistics happen.

You can find the fulcrum.

That’s the challenge – and the opportunity – we want to leave with you today.